Products

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

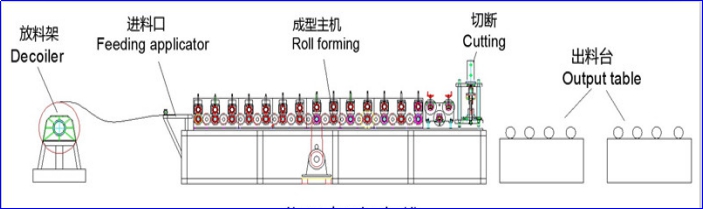

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

1. Strength and rigidity

The floor decking is made of high-strength steel bars with excellent compression and bending resistance. They are able to share and transmit large loads and maintain structural stability.

2. Lightweight

Compared with traditional concrete floor slabs, floor decking is lighter, thus reducing the weight of the overall building. This not only reduces the load requirements of the building, but also simplifies the construction process and improves work efficiency.

3. Flexibility

Floor metal deck can be customized according to different design requirements to adapt to various complex building structures. Can be easily connected with other components to form a complete building system.

Metal Deck Roll Forming Machine

Specification

No. |

Number |

Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Notice

●Installation

If installation is needed, the seller will dispatch a technician to the buyer’s factory abroad to assist regulating the machine . The buyer should assist the seller to get the Chinese technician's visa and should pay for the round trip air ticket ,local accommodation.and $100/day.

If installation is needed, the buyer shall make the following preparation before arrival of technicians.

*Position the machine in the buyer’s factory.

*Prepare necessary electric wiring.

*Prepare material of trial running.

*Provide labors for assistance and installation during installation

Advantages

1. Construction is simple and fast, shortening the construction period

2. It replaces the traditional formwork and improves the shortcomings of the traditional formwork. After the concrete hardens, it plays the role of tensile steel bars, producing a combination effect.

3. It can be used as part of the structural strength to reduce material costs.

4. Easy to construct reinforcement, wiring and piping

5. Neat and beautiful appearance

6. Light weight, high strength, heavy load bearing and good earthquake resistance.

7. Metal deck roll forming machine can be widely used in various types of construction projects, such as residential buildings, commercial centers, factories, etc. The floor decking produced by it has excellent load-bearing capacity and durability, and can meet the needs of different construction projects.