Products

floor decking machine

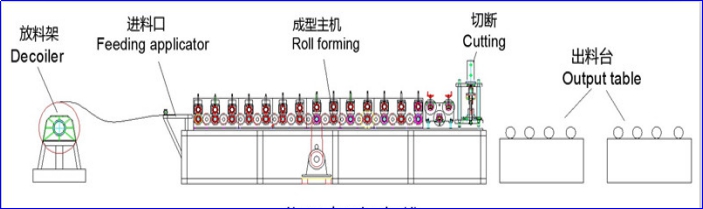

Deck Sheet Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

floor decking machine

Advantages of deck sheet

1. Strength and rigidity

The floor decking machine is made of high-strength steel bars with excellent compression and bending resistance. They are able to share and transmit large loads and maintain structural stability.

2. Lightweight

Compared with traditional concrete floor slabs, floor decking is lighter, thus reducing the weight of the overall building. This not only reduces the load requirements of the building, but also simplifies the construction process and improves work efficiency.

3. Flexibility

floor decking machine can be customized according to different design requirements to adapt to various complex building structures. Can be easily connected with other components to form a complete building system.

Deck Sheet Roll Forming Machine

Specification

No. |

Number |

Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Application

floor decking machine: The board is a new type of formwork that can replace the iron formwork before pouring. It has the advantages of convenient construction, reduced use of auxiliary wood materials, reduced urban noise, lower project costs and strong strength. The new floor decking does not use wood or steel and can save resources. It is suitable for schools, hospitals, residential buildings, private houses, commercial buildings, warehouses, hotels, factories, stations, libraries, tunnels, underground passages, and underground parking. Cast-in-place construction sites such as yards and bridge structures.

Adbantages

1. Floor structural support: Floor decking is mainly used for floor structural support of large buildings, including commercial buildings, schools, hospitals, hotels and other public places.

2. Strengthening of the building structure: Floor decking can strengthen the mechanical properties of the building structure, thereby making the building stronger, more stable and safer.

3. Sound insulation between floors: Floor decking has good sound insulation effect, which can avoid the transmission of noise between floors and further improve people's quality of life.

4. Save time and effort: Because the floor deck is light in weight, it saves time and effort in installation. The traditional brick-concrete floor structure requires a longer time and more labor to install.。