Products

Steel Sheet Floor Deck Roll Forming Machine

Steel Sheet Floor Deck Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

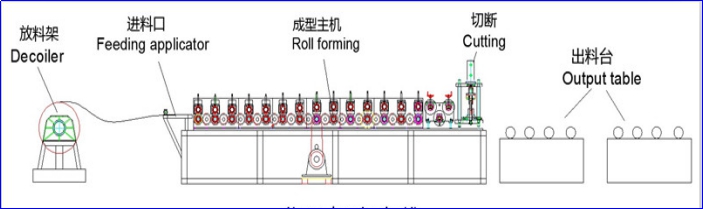

Steel Sheet Floor Deck Roll Forming Machine

Steel Sheet Floor Deck Roll Forming Machine

It is mainly composed of a combination of steel and concrete and has the advantages of high strength, good plasticity and toughness, fire resistance, and easy processing and installation. Floor decking has a wide range of applications, including industrial buildings, public buildings, commercial buildings, residential buildings, etc. It is especially suitable for large-span, high-rise and special-structure buildings. This building material has been widely used in the construction field due to its high strength, good plasticity and toughness, good fire resistance, easy processing and installation, economical and environmentally sustainable.

Steel sheet floor deck roll forming machine. The types of floor decking include open floor decking, closed floor decking, disassembly-free steel truss floor decking, etc. Open floor decking, also known as corrugated web-type steel-concrete composite structure, has high strength, good plasticity and toughness, and its fire resistance is very good. It is suitable for occasions with high fire protection requirements such as high-rise buildings and public places. Closed floor decking has the characteristics of light weight, high strength, and good seismic resistance, and is widely used in the field of steel structure construction. The disassembly-free steel truss floor deck has the advantages of waterproof and moisture-proof, stable and reliable, anti-corrosion and insect-proof, and simple construction. It is widely used in tunnels, underground passages, villas, commercial buildings, industrial buildings, bridges, residences, apartments, schools, public facilities, etc. All construction cast-in-place locations.

Steel Sheet Floor Deck Roll Forming Machine

Specification

No. |

Number |

Steel Sheet Floor Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Features

1. Efficient production capacity: Steel sheet floor deck roll forming machine uses high-strength steel as raw material. After precise processing and heat treatment process, it has high strength and durability, and can meet the needs of large-scale construction projects. At the same time, the metal decking machine adopts a continuous production method with high production efficiency, which can greatly shorten the construction cycle of construction projects.

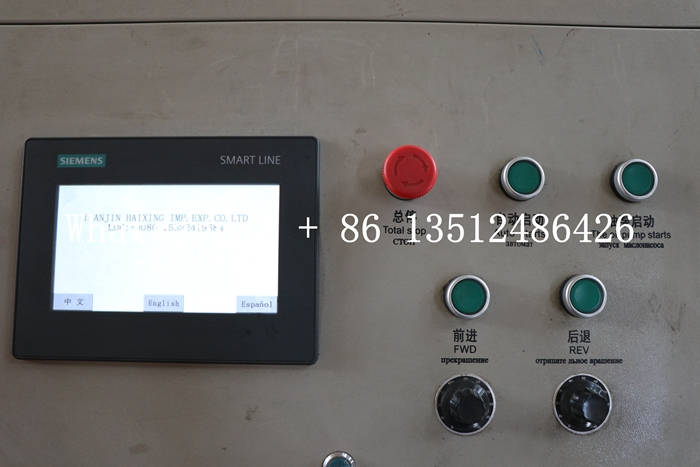

2. Precise automated control system: The steel sheet floor deck roll forming machine adopts an advanced automated control system, which can achieve precise parameter settings and adjustments to ensure product quality and stability. At the same time, the system can also monitor the operating status of the equipment in real time, discover and solve potential problems in a timely manner, and ensure the stability and reliability of the equipment.

3. Easy to operate: The steel sheet floor deck roll forming machine's operation interface is simple and clear, and the operation is convenient and fast. After simple training, operators can master the operation skills of the equipment and get started quickly. In addition, the machine is equipped with various safety protection devices to ensure the safety of operators.

4. Energy saving and environmental protection: The steel sheet floor deck roll forming machine adopts advanced energy-saving technology, which can significantly reduce the energy consumption of the equipment. At the same time, the noise and vibration generated by the machine are also effectively controlled, complying with environmental protection requirements.