Products

Metal Decking Machine

Metal Decking Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Metal Decking Machine

Metal Decking Machine

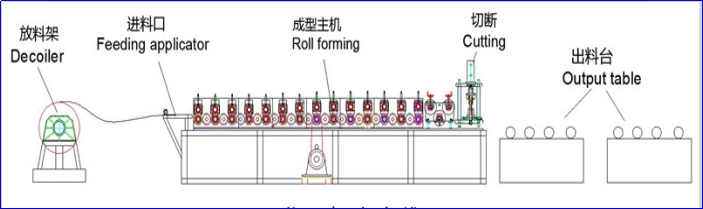

Metal decking machine is mainly composed of a discharge machine, a feed introduction platform, a forming host, a forming cutting device, a hydraulic station, and an electric control cabinet.

Metal decking machine adopts hydraulic drive and automatically cuts off after forming, without deformation or waste.

The products produced by floor decking machine equipment have the characteristics of light weight, high load-bearing capacity and good durability, and are widely used in multi-high-rise steel structure buildings.

Metal Decking Machine

Specification

No. |

Number |

Metal Decking Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Machine details

|

|

Name: Feeding Table

The feeding operation is simple and quick to get started. The hand wheel adjusts the feeding opening to easily adjust the feeding width. The roller belt plate prevents scratches. |

|

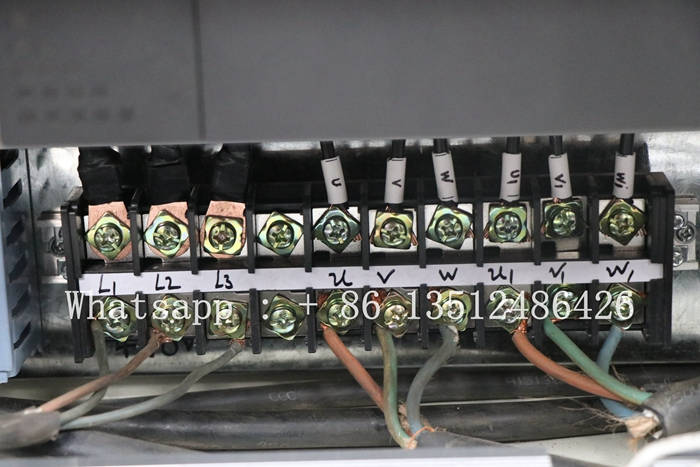

Name: Control cabinet Adopting programmable PLC control system and frequency converter for speed regulation, the operation is simple and user-friendly. |

|

|

|

Name: Computer Control Cabinet Touch Screen:Delta Frequency system:Delta The computer control cabinet needs only 3 connecting wiresL1,L2,L3, which is very easy to connect The 360-degree rotating touch screen with in Chinese, English and Spanish lan |

Features

1. Efficient production capacity: Metal decking machine uses high-strength steel as raw material. After precise processing and heat treatment process, it has high strength and durability, and can meet the needs of large-scale construction projects. At the same time, the metal decking machine adopts a continuous production method with high production efficiency, which can greatly shorten the construction cycle of construction projects.

2. Precise automated control system: The metal decking machine adopts an advanced automated control system, which can achieve precise parameter settings and adjustments to ensure product quality and stability. At the same time, the system can also monitor the operating status of the equipment in real time, discover and solve potential problems in a timely manner, and ensure the stability and reliability of the equipment.

3. Easy to operate: The metal decking machine's operation interface is simple and clear, and the operation is convenient and fast. After simple training, operators can master the operation skills of the equipment and get started quickly. In addition, the machine is equipped with various safety protection devices to ensure the safety of operators.

4. Energy saving and environmental protection: The metal decking machine adopts advanced energy-saving technology, which can significantly reduce the energy consumption of the equipment. At the same time, the noise and vibration generated by the machine are also effectively controlled, complying with environmental protection requirements.