Products

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Metal Deck Roll Forming Machine

Metal Deck Roll Forming Machine

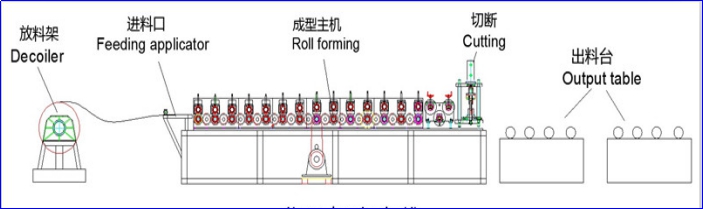

Floor deck is formed by cold-rolling steel plates (Cold Roll Forming is a multi-pass forming roller configured in sequence, which continuously rolls coils, strips and other metal plates). A plastic processing process that bends the ground laterally to make a specific cross-section profile), whose cross-section forms a V-shape, U-shape, trapezoid or similar shapes, mainly used for floors.

Metal Deck Roll Forming Machine

Specification

No. |

Number |

Metal Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

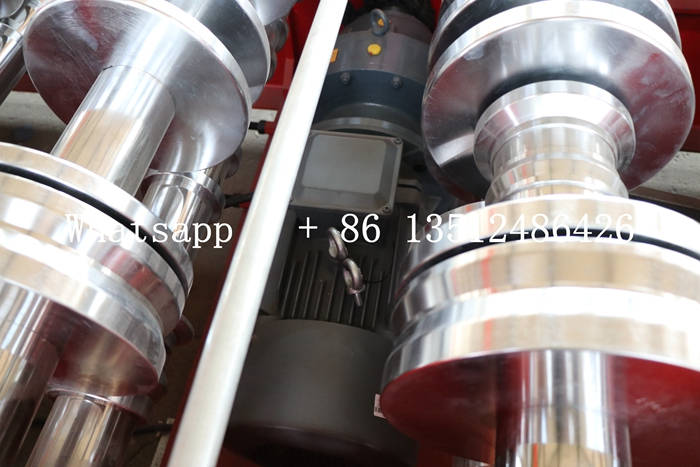

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Advantages

1. Strength and rigidity

The floor decking is made of high-strength steel bars with excellent compression and bending resistance. They are able to share and transmit large loads and maintain structural stability.

2. Lightweight

Compared with traditional concrete floor slabs, floor decking is lighter, thus reducing the weight of the overall building. This not only reduces the load requirements of the building, but also simplifies the construction process and improves work efficiency.

3. Flexibility

Floor metal deck can be customized according to different design requirements to adapt to various complex building structures. Can be easily connected with other components to form a complete building system.

Features

1: Metal Deck Roll Forming Machine. It adapts to the requirements of rapid construction of the main steel structure, can provide a firm working platform in a short time, and can adopt the flow construction of laying profiled steel plates on multiple floors and pouring concrete slabs in layers.

2: Metal Deck Roll Forming Machine. During the use stage, the floor deck serves as the tensile steel bar for the concrete floor slab, which also increases the stiffness of the floor slab and saves the amount of steel bars and concrete.

3: Metal Deck Roll Forming Machine. The embossing on the surface of the profiled board creates the maximum bonding force between the floor decking and the concrete, making the two form a whole. Together with the stiffening ribs, the floor decking system has a high bearing capacity.

4: Metal Deck Roll Forming Machine. Under cantilever conditions, the floor decking only serves as a permanent formwork. The length of the overhang can be determined according to the cross-sectional characteristics of the floor deck. In order to prevent the cantilever plate from cracking, it is necessary to add negative reinforcement at the support according to the design of the structural engineer.