Products

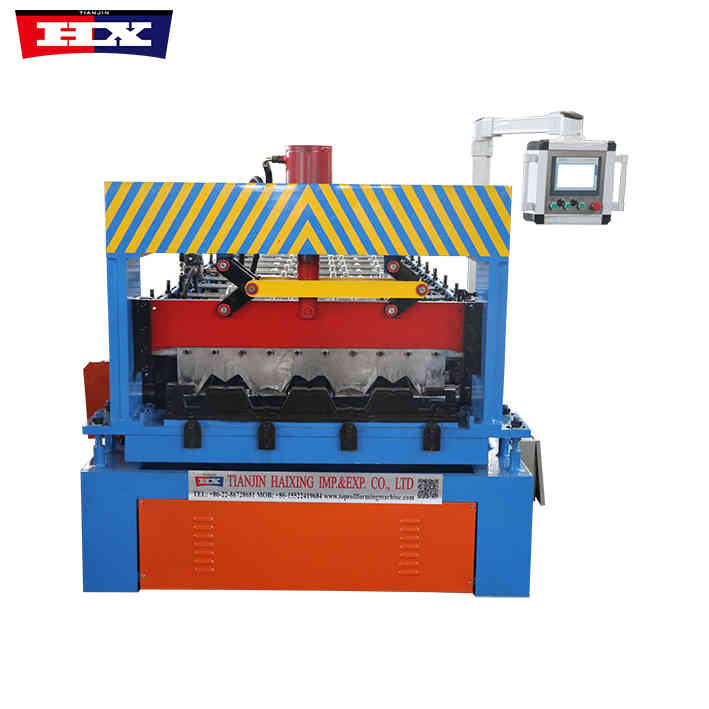

Customized Floor Decking Machine

Customized Floor Decking Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Customized Floor Decking Machine

Customized Floor Decking Machine

1. Improve production efficiency: The floor decking machine adopts automated control systems and digital technology during the production process, which can greatly improve production efficiency and reduce labor costs.

2. Improve product quality: Digital control is used in the production process of the floor decking machine to ensure that the floor decking produced meets quality standards.

3. Cost savings: Using floor decking machines to replace traditional production methods can not only save labor costs, but also reduce errors caused by human operations.

4. Easy to operate: The floor decking machine uses digital control technology and is easy to operate. Personnel only need to receive certain product operation training before they can get started.

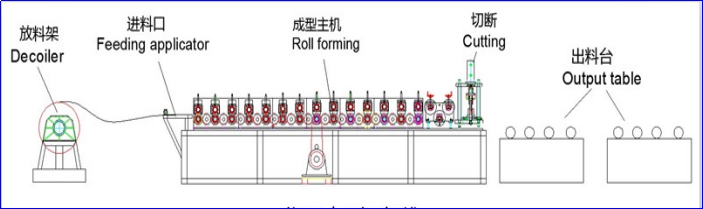

Customized Floor Decking Machine: Uncoiling → Guided feeding → Roll forming → Cutting to fixed length

Specification

No. |

Number |

Customized Floor Decking Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Parts of machine

|

|

Name: Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron. |

|

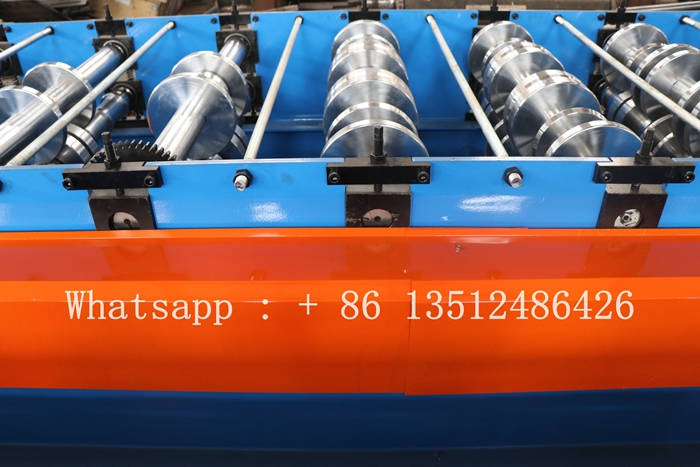

Name: Main Roll Forming Machine Material of rollers:High grade 45# Forging Steel ,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

|

|

|

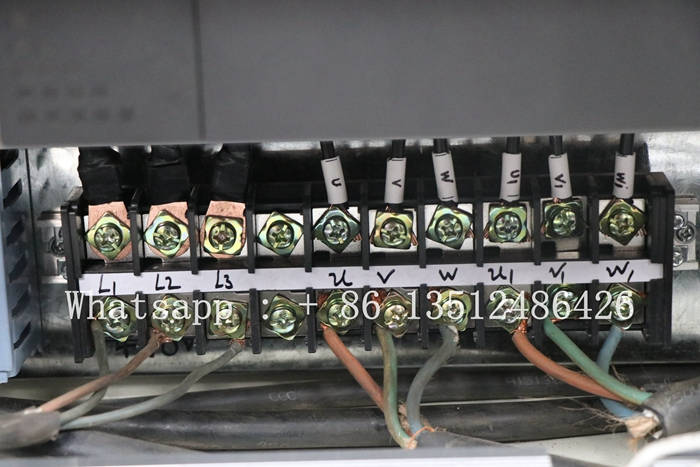

Name: Computer Control Cabinet Touch Screen:Delta Frequency system:Delta The computer control cabinet needs only 3 connecting wiresL1,L2,L3, which is very easy to connect The 360-degree rotating touch screen with in Chinese, English and Spanish language |

F&Q

1. Q: Can you provide some spare parts?

A: Yes, of course. We will loading some quick-wear parts together with the machine.

2. Q: Does one machine can only produce one style panel profile?

A: Not exactly, we have double or three layer machine, one machine can produce 2 to 3 profile.

3. Q: Pament Terms

A: we can accept TT and TT+LC.

4. Q: What information you need prepare before quote me?

A: best send us your profile and raw material detail, or we can custom-made according your demands.

5. Q: Is the machine automatic?

A: Yes,it can be manual or automatic