Products

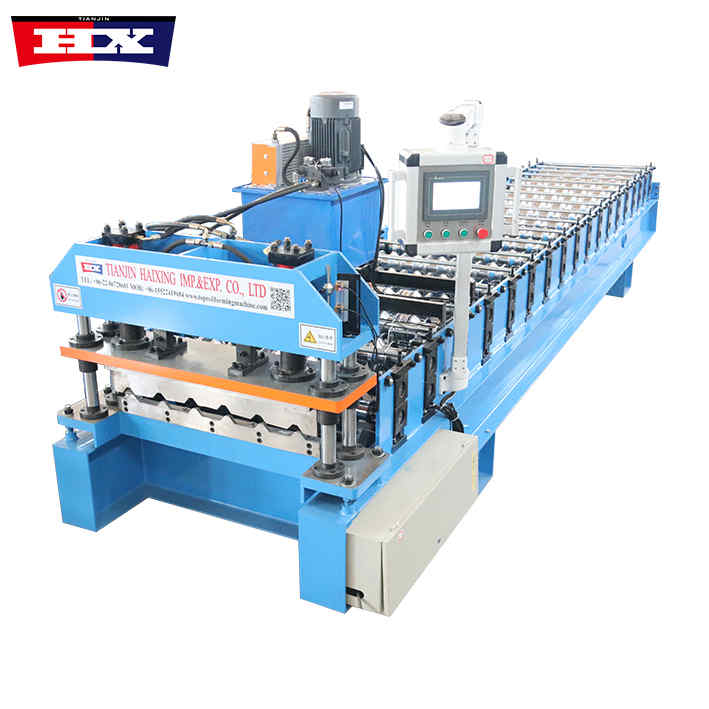

Trapezoidal Roof Sheet Making Machine

Trapezoidal Roof Sheet Making Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Trapezoidal Roof Sheet Making Machine

Trapezoidal Roof Sheet Making Machine

Trapezoidal Roof Sheet Making Machine

Specification

No. |

Number |

Trapezoidal Roof Sheet Making Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 18 |

| 19. | Size | 9000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Application

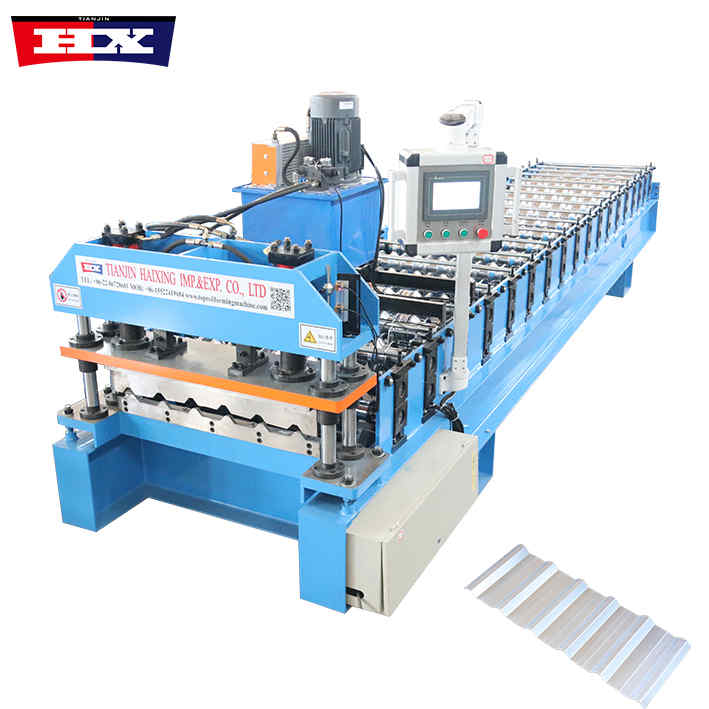

1. Construction field: The trapezoidal roof sheet making machine is mainly used to produce trapezoidal tiles for various constructions, such as flat to slope, roof waterproofing, etc.

2. Garden landscape: The trapezoidal roof sheet making machine can also be used to produce trapezoidal tiles for various garden landscapes, such as flower stands, walls, pavilions, etc.

3. Other fields: such as highways, railways, water conservancy and other infrastructure construction also need to use trapezoidal roof sheet making machine.

Operation

1. Preparation work

Before formal operation, the following preparations need to be carried out:

1). Check whether the parts of the tile press are intact and whether there are any looseness or other abnormalities;

2). Prepare the tiles to be pressed and the tools needed for the tile press;

3). Provide safety training to operators so that they can understand relevant safety knowledge and understand the structure, performance and operating procedures of the machine.

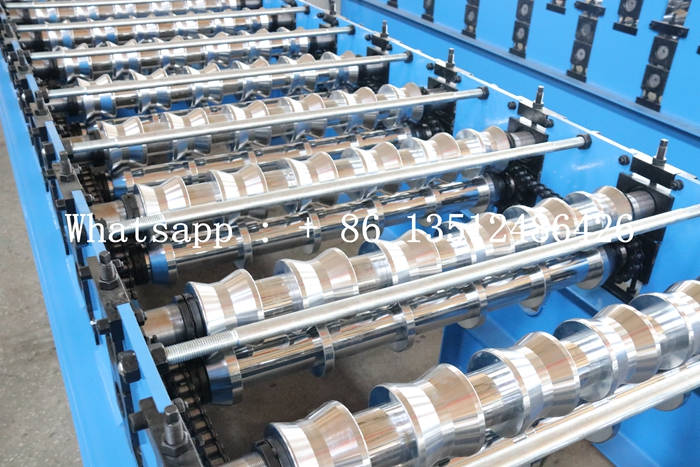

2. Debugging the machine

1). Adjust the tool

Tool adjustment is an important link to ensure the tile forming effect. The operator needs to adjust according to the thickness and geometric parameters of the tile to ensure that parameters such as tool height and deviation angle meet the requirements.

2). Adjust the feeding device

The adjustment of the feeding device is as important as the adjustment of the tool. It is necessary to ensure that the feeding state is stable, the feeding transmission part is not loose, and the feeding height can meet the production requirements.

3). Check the oil circuit

Check whether the oil circuit of the hydraulic system is smooth and whether there is leakage, which needs to be repaired in time.

3. Adjust pressure

1). Adjust the pressure value

The pressure value of the tile press needs to be adjusted according to different tile materials and design parameters. Generally, the pressure range of the tile press ranges from 100-200t. Operators need to adjust according to production requirements.

2). Adjust the pressure holding time

The pressure holding time is adjusted to ensure the quality of the tiles after they are formed. The time is generally 1-5 seconds. Holding time that is too long will result in reduced output, and holding time that is too short will result in low quality finished products.