Products

Steel Coil Decoiling Machine

Steel Coil Decoiling Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time:20 working days

Shipping Time : 40 days

Port : Tianjin

Steel Coil Decoiling Machine

Steel Coil Decoiling Machine

Working principle

Steel coil decoiling machine is a device that is powered and controlled by a hydraulic system. It consists of a host machine, a hydraulic system, an electrical control system and other parts. The host part includes hydraulic cylinders, reel bearings, transmission systems, etc. The hydraulic system consists of a fuel tank, a pump station, oil pipes, oil pipe joints, etc., and controls the lifting, forward and backward movement, up and down swing, etc. of the uncoiler. The electrical control system is responsible for the interlocking, protection, and operation of each part of the machine.

Specification

No. |

Number |

Steel Coil Decoiling Machine |

| 1. |

Hydraulic pump station |

4kw (Electromagnetic valves) |

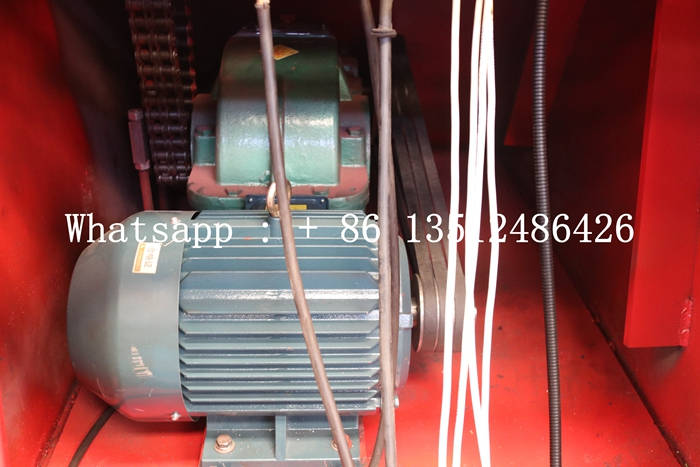

| 2. | Main motor | 5.5kw |

| 3. | Main frame | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Main shaft | 203*55 seamless pipe |

| 7. | Coil inner diameter | 470-530±20mm |

| 8. | Cylinder | 1 Diameter 125mm |

| 9. |

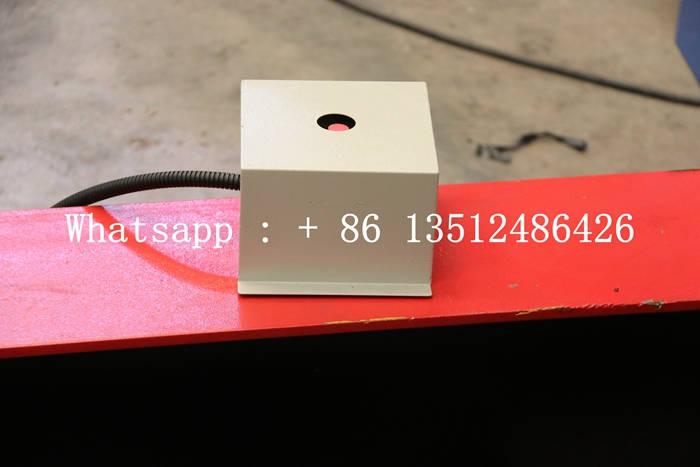

Electrical control system |

Delta Inverter(7.5kw) Domestic Electronic Control System |

| 10. | Feeding width | 0-1500mm |

| 11. | Weight capacity | 10 tons |

| 12. | Trolley |

Width : 1.1m Length : 0.9m |

| 13. | Trolley track |

Width : 1.15m Length : 2.5m |

| 14. | Trolley route |

High : 300mm Length : 2.5m |

| 15. | Trolley wight | 0.8 tons |

Optional Decoiler

1. The load capacity should consider the material width, material thickness, loading weight, coil exterior, and coil outer diameter requirements of the metal coil.

2. Select the configuration device considering the speed of discharging and the degree of operation automation;

3. Comprehensively consider the space required, each material change time, and the required chassis required for the induction control method.

Maintenance

1. Before use, please check the specifications of the decoiler, the material width and thickness, and the loading weight. Overloading is strictly prohibited;

2. For long-term use, bearing butter should be added once a week, the waste machine should be replaced every six months, and the amount should be eliminated to 1/3;

3. After long-term use, you should pay attention to check whether the bearings, bearing seats and screws on the machine are loose.