Products

Roofing Trapezoidal Sheet Roll Forming Machine

Roofing Trapezoidal Sheet Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Roofing Trapezoidal Sheet Roll Forming Machine

Roofing Trapezoidal Sheet Roll Forming Machine

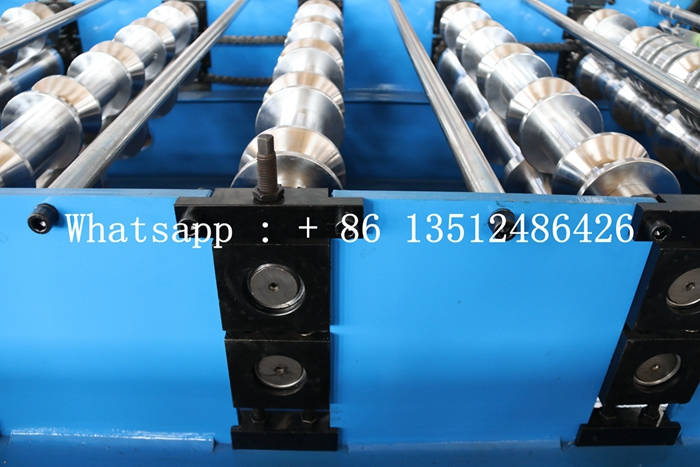

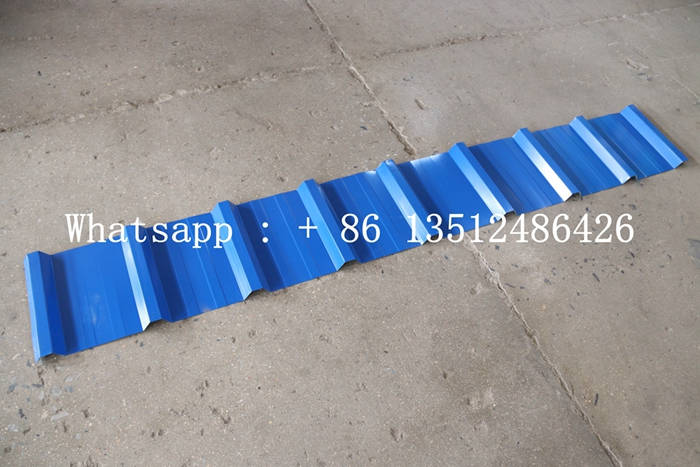

The roofing trapezoidal sheet roll forming machine is a device that uses mechanical principles to quickly press metal sheets into tile shapes. Its main function is to process metal sheets into metal tiles for building roofs and walls, providing the construction industry with higher-quality, practical and beautiful building materials. At the same time, the corrugated iron roofing sheet making machine can also produce metal tiles of different shapes such as arc shapes according to different needs by replacing different press tile molds.

Roofing Trapezoidal Sheet Roll Forming Machine

Specification

No. |

Number |

Roofing Trapezoidal Sheet Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 15 |

| 19. | Size | 7500mm*1500mm*1600mm |

| 20. | Weight | 6000kg |

Advantages

1. Efficiency: The roofing trapezoidal sheet roll forming machine uses advanced mechanical principles to quickly process metal sheets, maximize work efficiency, significantly save manufacturing costs, and provide a faster and more labor-saving solution for the construction industry.

2. Stability: The roofing trapezoidal sheet roll forming machine is made of high-strength materials, which can maintain stability during the working process, effectively prevent irregular tiles and deformation of tiles caused by problems with the machine itself, and has long-term stability work performance.

3. Diversity: The mold of the roofing trapezoidal sheet roll forming machine is replaceable and can produce metal tiles of different shapes such as arcs, etc., providing the construction industry with more diversified and diversified choices, and satisfying different customers and different needs. Requirements for building needs.

4. Aesthetics: The metal tiles produced by the roofing trapezoidal sheet roll forming machine are rich in color, with a variety of colors to choose from, and have a beautiful and elegant appearance, providing the construction industry with more beautiful and high-quality building materials.