Products

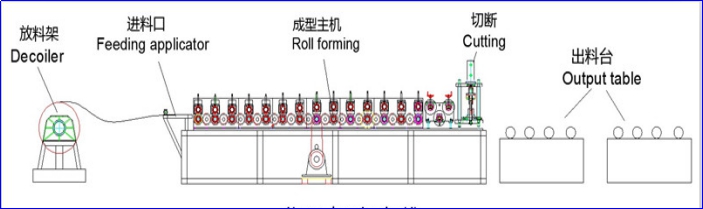

Deck Floor Roll Forming Machine

Deck Floor Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Deck Floor Roll Forming Machine

Deck Floor Roll Forming Machine

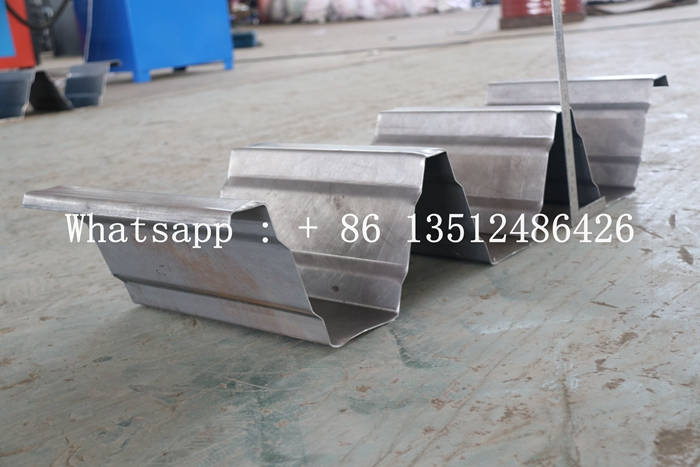

Floor decking is widely used in various construction fields such as residential, commercial, industrial, and public facilities.

1. In residential buildings, floor decks mainly bear floor loads and ensure the safety of residents;

2. In commercial buildings, floor decks can improve the space utilization of the building and reduce construction costs;

3. In industrial buildings, floor decks can improve Improve production efficiency and shorten the project cycle; 4.

4. In public facilities, floor decking can provide a safe and comfortable environment.

Floor decking is a floor slab used to carry and distribute building loads. It is mainly made of steel plates, steel bars, concrete and other materials. This type of floor slab offers significant advantages in building design and construction, particularly in providing structural strength, resisting seismic forces, and saving material.

The main function of floor decking is to provide structural support and distribute loads. In the floor structure of a building, the floor deck serves as the main load-bearing element, which can effectively distribute the weight of the building and other dynamic loads to the overall structure. This allows the building to maintain good structural stability and safety even under heavy loads.

In addition to providing structural support and dispersing loads, floor decking also has excellent seismic performance. Due to its own strength and stability, floor decking can effectively absorb and disperse earthquake forces, thereby reducing earthquake damage to buildings.

Deck Floor Roll Forming Machine

Specification

No. |

Number |

Deck Floor Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Performance

1. Save a lot of temporary formwork, omit all or part of the formwork support and reduce the amount of concrete;

2. Reduce the permanent load of the structure, which is more important for high-rise buildings and earthquake zones;

3. Save a lot of labor in transportation, stacking and installation;

4. Reduce the workload and facilitate Lay communication, electricity, heating and other pipelines, and can lay insulation, sound insulation, thermal insulation, vibration isolation and other materials to improve the floor performance and give full play to the good tensile strength and ductility of steel and the excellent compressive strength and large strength of concrete stiffness

Advantages

(1) Light weight

(2) High strength

(3) High stiffness

(4) Easy to update

(5) Construction is convenient and fast

(6) Structural requirements to facilitate industrial production of composite floor slabs