Products

Metal Deck Forming Machine

Metal Deck Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Metal Deck Forming Machine

Metal Deck Forming Machine

1. Metal Deck Forming Machine. High efficiency and energy saving: The floor decking machine adopts advanced control system and transmission system, which has the advantages of high efficiency and energy saving, and can greatly improve production efficiency and reduce production costs.

2. Metal Deck Forming Machine. High precision: The floor decking machine uses high-precision bearings and gears to ensure that the processed panels are accurate in size and standard in shape, effectively reducing the product defect rate.

3. Metal Deck Forming Machine. Strong adaptability: Floor decking and metal plates are suitable for processing various thicknesses and materials. At the same time, the shape and size of the plates can be adjusted according to customer needs.

4. Metal Deck Forming Machine. Easy to operate: The equipment adopts human-machine interface operation, which is simple and convenient to operate. It is also equipped with a variety of safety protection devices to effectively ensure the safety of operators.

Metal Deck Forming Machine

Specification

No. |

Number |

Deck Roll Forming Machine |

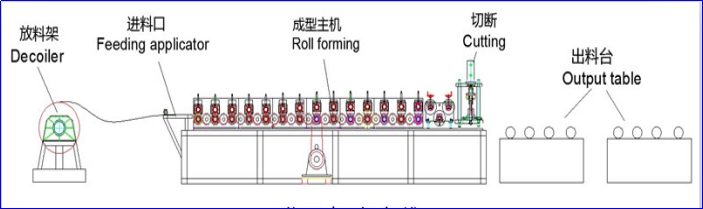

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Products details

|

|

Name: Motor

High power, fast operation, low motor noise, small vibration, good operating performance, not easy to burn the machine, and long use time |

|

Name: Feeding table Save human effort. Fully automatic control is adopted to ensure stable and smooth feeding, which improves efficiency and saves manpower. |

|

|

|

Name: Cutting head Easy to operate, the servo does not stop the machine for punching and shearing, and the product automatically falls into the bottom and is conveyed out of the machine by the belt. |

Application

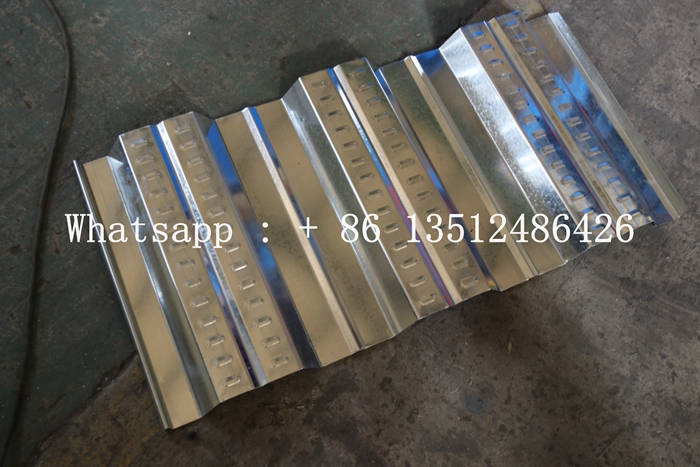

1. Floor decking is mainly used for decoration and reinforcement of roofs and exterior walls of high-rise buildings, as well as protection against various natural disasters.

2. Floor decking can also be used in the construction of large public facilities such as stations, airports, squares, and sports venues, and has great market prospects and application value.

Features

a. Light weight, high strength, heavy load-bearing, and good earthquake resistance;

b. Simple and fast construction, convenient assembly;

c. replaces traditional formwork and improves the shortcomings of traditional formwork;

d. Can be used as structural strength