Products

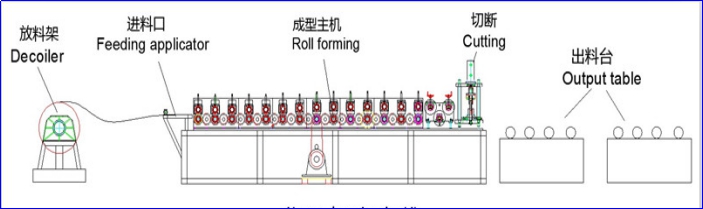

Glazed Roof Forming Machine

Glazed Roof Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.3-0.8mm

Produce Speed : 10-15m/min

Port : Tianjin

Glazed Roof Forming Machine

Glazed Roof Forming Machine

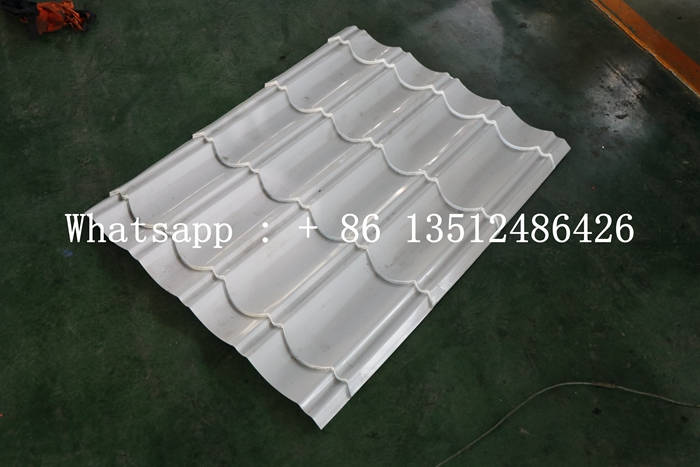

The glazed roof forming machine is a common building material processing equipment, mainly used to process various types of roof tiles, wall panels, building sheets and other materials.

Glazed Roof Forming Machine

Specification

No. |

Number |

Glazed Roof Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 350H Beam |

| 4 | Middle side | 16mm |

| 5. | Main motor | 5.5kw |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1 inch |

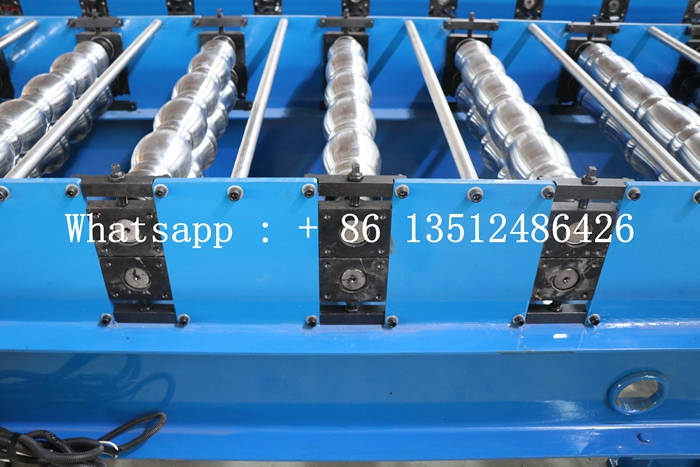

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ70mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.3-0.8mm |

| 18. | Rows | 9 |

| 19. | Size | 5000mm*1500mm*1600mm |

| 20. | Weight | 5000kg |

Operation

1. Turn on the power of the tile press and ensure that the power supply is stable.

2. Preheat the equipment. The preheating time may vary depending on the type and specifications of the tile press.

3. Prepare the tile materials that need to be processed and place them on the workbench of the tile press.

4. Adjust the parameters of the tile press. According to the material and size of the tile, set appropriate processing parameters, including pressure, speed, etc.

5. Program setup and loading. Load the tile design pattern to be processed into the control system of the tile press and make corresponding program settings

6. Start automatic processing. According to the set program, start the automatic operation mode and let the tile press machine process according to the preset patterns and parameters.

7. Monitor the processing process. Observe the processing process of the tile press, check the quality and processing effect of the tiles, and ensure the accuracy and consistency of the processing

8. End processing. After the processing is completed, stop the automatic operation mode of the tile press, disassemble the processed tiles, and prepare for the next batch of processing.