Products

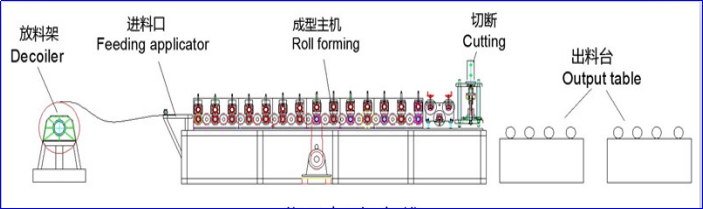

Steel Deck Roll Forming Machine

Steel Deck Roll Forming Machine

Voltage: 380v/220v 50hz 3p can be customized according to customer requirements

Production Time: 30-35 working days

Shipping Time : 40 days

Thickness : 0.8-1.5mm

Produce Speed : 10-15m/min

Port : Tianjin

Steel Deck Roll Forming Machine

Steel Deck Roll Forming Machine

Floor decking plays an important supporting role in building structures. It can withstand the weight and load of floors and through its strong structural properties

Provides solid support in construction. Floor decking is often used in cantilevered structures, long-span buildings, or projects that need to carry large loads.

1. Strong load-bearing capacity: The floor deck can withstand large pressure and shear forces and can meet the load-bearing requirements of the building.

2. Good durability: The floor decking is made of high-quality steel and has been treated with anti-corrosion and anti-rust treatments to have a long service life.

3. Convenient construction: The floor decking can be customized according to building requirements, and is easy and fast to install, which can effectively shorten the construction period.

4. Economical and affordable: The price of floor decking is relatively reasonable and can meet the budget requirements of different construction projects.

Steel Deck Roll Forming Machine

Specification

No. |

Number |

Steel Deck Roll Forming Machine |

| 1. | Operation style | Automatic |

| 2. | Raw materials | PPGI |

| 3. | Structure | 450H Beam |

| 4 | Middel side | 18/20mm |

| 5. | Main motor | 15kw*2 |

| 6. | Pump station | 4kw |

| 7. | Cutting type | Hydraulic cutting |

| 8. | Produce speed | 10-15m/min |

| 9. | Chain | 1.5/2 inches |

| 10. | Shaft material | Cr12MoV |

| 11. | Brand of electrical control cabinet | Delta or customized according to customer requirements |

| 12. | Touch screen/inverter | Delta or customized according to customer requirements |

| 13. | Rolling materials | Forged 45# steel with chrome plate |

| 14. | Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| 15. | Roller diameter | Φ85mm |

| 16. | Voltage | 380v 50hz 3p be customized |

| 17. | Thickness | 0.8-1.5mm |

| 18. | Rows | 26 |

| 19. | Size | 12500mm*1800mm*2000mm |

| 20. | Weight | 13500kg |

Advantages

1. High intensity

The floor deck is made of prestressed concrete, which is prestressed during the production process to obtain higher strength. This allows the floor deck to withstand greater loads and external forces, ensuring the safety and stability of the building structure.

2. Save materials

Because the floor decking is prefabricated in the factory, the production process is more precise and the material utilization rate is higher. Compared with traditional on-site cast-in-place floor slabs, floor decking can save a lot of concrete and steel materials, reduce resource waste, and is more environmentally friendly.

3. Improve construction quality

The prestressed design of floor decking can reduce the risk of deformation and cracking, improve construction quality and the overall performance of the building. Due to the characteristics of prestressed concrete, floor decking can better resist deflection and vibration, enhancing the earthquake resistance of the building.